Category:Torpedo (UK)

The British government manufactured torpedoes bearing distinctive marks such as R.L., R.G.F. and R.N.T.F. in Woolwich and then Greenock from 1872 through the end of World War I and beyond.

Production in Woolwich

The British government started manufacturing 16-in torpedoes under the auspices of the Royal Laboratory in Woolwich in 1872. Production under the stamp "R.L." continued until the Woolwich factory was transferred to the Royal Gun Factory in 1890, when the stamps were accordingly changed to read "R.G.F.".[1]

Private Production

To augment national production, additional domestic manufacturing to the same designs was contracted to Messrs. Greenwood and Batley in Leeds, starting in 1886. Apart from minor differences in material, these were to the same Woolwich designs and we categorise them here, as being of national manufacture.[2]

Greenock

In 1911, the R.G.F. factory in Woolwich shut down, and transferred its operations to the new Royal Navy Torpedo Factory in Greenock. The nation's torpedoes would henceforth bear the "R.N.T.F." stamp.[3]

Superintendents

- Retired Captain Cecil R. Acklom, 3 September, 1909[4] – 5 March, 1919[5]

Assistant Superintendents

- Acting Commander William H. S. Ball, November, 1918[6] – 26 November, 1923[7]

Private Designs

This is in contrast to other torpedoes that Britain used, such as those purchased from the Whitehead company, which were variously described as being Fiume or Weymouth torpedoes, after their places of manufacture. Those torpedoes are not categorised herein, but may be mentioned in passing.

Types

Torpedoes were either 14-, 15- (uncommon), 16- (also uncommon), 18- or 21-inches in diameter. They were either "heaters" or not. Some lacked gyroscopes, particularly those manufactured before 1900.

One important distinction was what small external fittings the torpedo was equipped with to engage its tube:

- "Side Lugs" (S.L.) suitable to A.W. tubes or perhaps submerged tubes firing ahead or astern

- "Hook Brackets" (H.B.) were suitable for submerged broadside tubes and generally took a knot of the same torpedo's speed were it equipped as S.L.

- "T Brackets?" (T.B.) or "Vertical Brackets" (V.B.), "Guide Strip" (G.S.)[8] for firing from beam tubes of "E" class subs (or from bow or stern if those were removed), as these determined what type of tube could fire them.

Some common suffixes are: "H." for torpedoes converted to "heater" torpedoes from cold designs (heaters designed with this from the get-go do not have this suffix)[9], "R.A.F." for torpedoes intended to be dropped from airplanes (to be painted green from 1918), and "S." denoted torpedoes adapted for fire from submarines.

"A.W." means "above water", as opposed to "S.F." for "submerged fire".

In notes on trial runs, "B.S." means "broke surface".

Other terms:

- "H.S." means a high speed (short range) setting

- S.R. means "short range" - some early torpedoes were hard-plumbed to deliver this

- L.R. means "long range" - ditto

- "E.R." (often "E.R. 3") means an extended range (low speed) setting.

New tail fittings proposed in 1915 were broadly adopted for all new torpedoes after 1916, including the 18-in Mark VII****. These torpedoes were to be H.B. 1 and S.L. 1, and reduced the chance of hanging up in the tube.[10][11]

Arc of History

The Royal Navy first evaluated Whitehead torpedoes (16-inch and 14-inch) in extensive tests in 1870, and concluded they were an important weapon although the range at which a hit seemed likely was about 100 to 300 yards. Particularly persuasive was when a test with a torpedo net missed the net and the target ship was immediately sunk.[12]

The Royal Navy licensed Whitehead's depth-keeping secret and in 1872 started manufacturing 16-inch torpedoes at the Royal Laboratory in Woolwich. In 1877, production switched to a new 14-inch torpedo capable of making 18 knots to 600 yards with a warhead of 26.5 pounds. By 1884, the speed had increased to 24 knots. In 1886, Messrs. Greenwood and Batley in Leeds started manufacturing torpedoes to R.G.F. designs. Whitehead's work for the Royal Navy continued, yielding torpedoes of 28-29 knots over 800 metres by 1889, with warheads of 199 pounds guncotton.[13]

Manufacture of 14-inch torpedoes ceased in 1906.[14]

Use of 21-inch torpedoes for A.W. started in 1910, and submerged fire in 1911.[15]

"Fiume" and "Weymouth" descriptors apply only to torpedoes made by Whitehead and Company, Fiume.[16]

In November 1915, Jellicoe ask that torpedoes be modified to permit extreme range fire at lower speeds, and it was hoped that 21-in Mark II**** torpedoes might achieve a 18,000 yard range might be achieved at 19-20 knots running speed, later adjusted to 19,000 yards at 18 knots following experimental tests in February 1916 in Weymouth Bay. Production was ordered to deliver torpedoes capable of 17,000 yards at 18 knots, expecting a 25% failure for torpedoes to achieve this performance. Only those torpedoes with "B" or "B2" generators would receive the modification, as the "A" types were unreliable in ignition. Two torpedoes of the latest type in in each battleship and battlecruiser were to be adapted to this newly designated E.R. type. An unpleasant artifact was that these torpedoes could not readily be set to another speed by the normal means. Experiments with 18-in Mark VII*** torpedoes showed them to be far less reliable, but test runs with the altered 21-in torpedoes showed the 25% failure rate estimate to have been considerably high.[17][18]

Also in 1916, delivery of E.R. torpedoes then extended to light cruisers with submerged tubes, two per ship and to cruisers armed with 18-in torpedoes. Designs for torpedoes with three, rather than two speed-settings were undertaken to alleviate the concern with the fixed-speed E. R. design, resulting in the 21-in Marks II***** and IV.[19]

Lessons drawn from Jutland sparked the idea that the 10,000 yard setting for torpedoes was nearly useless, but that there might be a better setting that was between 10,000 and the E. R. figure of 18,000 yards. A meeting under Admiral Sturdee with Vernon representatives yielded a report stating:[20]

- 15,000 yards should be the new standard long range, given North Sea visibilities of 6-7 miles

- torpedoes set to a 10,000 yard range will seldom find occasion for use, especially from capital ships.

- longer ranges are also desireable for light ships to reduce the chance the firing will be observed by the enemy

- consequently, all torpedoes should be capable of the standard 15,000 and 4,500 yard settings

- capital ships and light cruisers with submerged tubes should carry two E. R. torpedoes capable of a third setting for 18,000 yards at 19.5 knots

- all 21-in torpedoes should be updated to be able to be switched to the standard settings without parting the torpedo, pending a design for this

- future priority should be for long range, with speed being a secondary priority.

- 18-in torpedoes on capital ships should be modified to permit the longest range possible at no less than 17-18 knots

This report resulted in the decision to design fittings for torpedoes capable of being quickly adjusted to three settings (the 4,500 yard figure may have been reduced to 4,000). The 21-in Mark II***** started delivery in November 1916 embodying these features, and new ships completed in November were to receive two each, and all destroyers were to be uniformly equipped with these torpedoes. Details of them are in T.O. No. 195 of 1916.[21]

The first 21-in Mark IV torpedoes began being issued in February 1917.[22]

A large programme was instituted to quickly convert existing torpedoes to the standard. Conversions got underway in December 1916, starting with the first half-flotilla of the Thirteenth Destroyer Flotilla with wide scale execution in place by the end of 1916.[23]

Heater Torpedoes

The Royal Navy placed its first orders for heater torpedoes in 1907, burning "Broxburn Lighthouse Oil", similar to paraffin. Elswick heaters, a simple jet of fuel lit by a cartridge called an "igniter" were simpler but less efficient than the fuel-air R.G.F. heater system.[24]

Gyroscopes

The Royal Navy first started ordering and installing "Weymouth pattern" gyroscopes provided by Whitehead in 1898. Satisfaction with early results[26] was such that by 1900, all the new manufacture torpedoes were having gyros installed, and a brisk trade in retrofitting existing torpedoes was kicked off.[27]

By the end of 1900, 1,250 gyros had been ordered and something over 80 ships were equipped with gyroscopes, though it was commonplace at this point to have one gyro per every two gyro-capable torpedoes.[28]

Originally, and the general case, gyroscopes only controlled the vertical rudders of the torpedo to keep it on a perfectly straight course. Previous to their use, it was incumbent on torpedomen to carefully adjust the rudders into a fixed position so the individual torpedoes would roughly go straight on practice runs (much as a child might tune the "flaps" of a paper airplane) and to try to avoid or take into account any deflections in heading that might occur as the torpedo entered the water medium.[29] The gyroscope was intended to render this adjustment dynamic, though practical use often resulted in significant deviations of heading.

By 1910, the dirigible nature of a gyro torpedo inspired creation of gyro angling and pattern running designs.

Gyro Angling

The idea of angling gyros for submarine firings was proposed in 1907 by the Inspecting Captain, and trials held at Portland Range.[30]

Gyro angling was trialed and refined in 1910-1911, when Vernon is sounding out ideas for data instruments to convey gyro angles as part of a larger plan for communications between torpedo control and firing positions, as such torpedoes are "now under trial". The initial design indicates angles up to 40 degrees on either side, in 10 degree increments.[31] They were under trial in the Home Fleet in 1911.[32]

Pattern Running

Orion tested two 21-in pattern running ("gyro control") torpedoes in 1913.[33] They used "Type A" oval-running gear created by Lieut Francis Hugh Sandford. One test run was perfect, producing a hit, and the second run had a much greater radius to its second turn owing to a fault that seemed correctible.

Two other torpedoes tested at Vernon had "Type B" S-zig-zag running gear, where the turns would alternate left and right.

The "A" gear caused a turn of 16 points after running a predetermined distance, thereafter repeating the turn every 1,000 yards to describe an oval 150 yards wide. The gyro was modified so that it would rectify small errors in the turns to exactly 16 points. The initial tests were successful, but an improved design was to be created for adoption in new torpedoes. The "B" type also seemed to work nicely, but the mechanism was more complex and there was no clear idea as to whether the S pattern offered a tactical advantage to offset this complexity, and so trials were closed in 1913.

In 1914, trials of "A" type were dropped, intended to be re-opened later with 2,000 yards rather 1,000 yards danger area. Those torpedoes being tested with "B" type gear were to be returned to depots for restoration to Service patterns, as the mechanism was deemed impracticable.[34]

The basic mechanism had not been further improved by 1916, but they were being ordered for manufacture with a priority being placed on submarine torpedoes.[35]

Depth Keeping Mechanism

The most vital technology embodied in Whitehead's work was the design of a depth-keeping mechanism that prevented "porpoising". Previous torpedoes had used a manometer to measure their depth, and this input was tied to the angle of the horizontal rudders to cause the weapon to attempt to keep the desired depth. Whitehead saw that this one datum was not enough information from which to design a good control system. He added a pendulum (in some implementations, a one-dimensional flywheel gyroscope), which provided a measure of the torpedo's pitch angle in the water. This angle was, at small angles, proportional to the rate of change of depth as the torpedo sped forward through the water; Whitehead was adding a derivative to the control system. His "secret" was to create a system that could combine (depth * A) and (rate of change of depth * B), where A and B were tunable coefficients, and this greatly improved the fluidity of control and prevented wild fluctuations about the set depth.

The Royal Navy eventually came up with its own designs called the "Ulan" and "Weymouth" systems. By 1913, the "Ulan" system was found too finicky for continued development.[36]

Pistols

The pistol is the warhead firing mechanism for a torpedo.

Procurement and Practice

1880

16-in torpedoes were 74.6% successful, and 14-in torpedoes 70.6% so.[37]

1881

1,329 runs made, 70% successfully.[38]

Reports of incremental improvements to existing Mark I and II R. L. torpedoes.[39]

Four "new pattern" 14-in Fiume Mark III torpedoes were purchased from Whitehead and evaluated at Fiume. It was found to have 3 knots advantage over the 14-in Mark I torpedo R.L. at 600 yards range. A tear-down in England showed its engine had 17% more power than the Brotherhood engine in the 14-in Mark II torpedo R.L.. However, in short 250 yards tests limited by a canal, the Fiume torpedo was 0.9 knots slower than the Mark II R.L.[40]

1882

1,039 runs made, 86% successfully.[41]

The 14-in Mark III torpedo was introduced. Among 17 innovations listed for it was that each torpedo's trial speed was stamped on the air chamber.[42]

1883

1,164 runs made, 78% successfully.[43]

An experimental 14-in Mark IV torpedo was constructed using the 14-in Fiume Mark III torpedo air chamber and R.L. afterbody with the 16-in fins exchanged for 14-in ones (the torpedo's own diameter). It made 23.7 knots at 600 yards with a 65 pounds guncotton charge.[44]

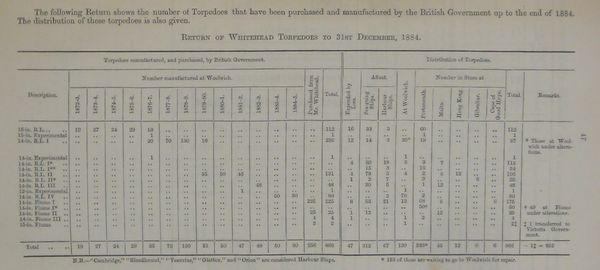

1884

1,586 runs made, 82% successfully.[46]

Fifty "comparatively obsolete" 14-in Fiume Mark I torpedoes were being altered by Whitehead, keeping only the air chambers and otherwise entirely altering the internal and external form to a new Mark I* standard. The new torpedoes were shorter (13.25 feet rather than14 feet, 4.25 inches) and less "pointy" than before, reflecting the new understanding of the counter-intuitive fact that a needle-like shape was less efficient than a bluff one.[47]

Also, Whitehead had altered 12 and was to alter 12 more 14-in Fiume Mark II torpedoes to make them more reliable.[48] He was also building two new 14-in torpedoes that were just 11 feet long, hoping to carry a 39 pound charge to 440 yards at 22 knots.[49]

In addition, the Annual Report of the Torpedo School for 1884 includes detailed accounting of torpedoes on hand, lost, disposed of, undergoing alteration, and under manufacture. These are presented so clearly that we shall produce them here in as originally presented.

1885

1,949 runs made, 88% successfully.[50]

Most substantial, however, was the purchase of 220 Mark IV Fiume torpedoes from Whitehead, some in hand and the balance expected by the end of the fiscal year.[51]

Ten 12-in, 9/5 foot long Fiume torpedoes were also ordered, with the idea that these might prove suitable for small boats.[52] Lastly, domestic production was to be diversified by having Messrs. Greenwood and Batley of Leeds construct 100 14-in Mark IV torpedoes at a rate of 20 per year. The Mark IV torpedoes had proven successful, and did 23.69 knots over 600 yards with a 70 pound charge of dry gun-cotton.

At the same time, the Royal Laboratory at Woolwich was making 200 14-in Mark V torpedoes, the first two having already been tested and proven satisfactory. Their design improvements were enumerated as nine in number. Deviation in the 24 runs of the two test torpedoes had not exceeded 6 feet at 400 yards, and they had made speeds of 21.5 and 22.25 knots - about that of the Mark IV torpedoes - though improvement upon this was expected as the water was 45 degrees.

Lastly, the Woolwich plant had been expanded, at a cost of 40,000£, and it was now estimated to be capable of making 250-300 torpedoes per year.[53]

One hundred phosphor-bronze 14-in torpedoes were purchased from Schwartzkopff of Berlin, and the first 50 received.[54] Eleven other Schwartzkopff torpedoes were purchased from China at Hong Kong for use by torpedo boats in the harbour. These were found similar to 14-in Fiume Mark II torpedoes, but almost free of corrosion due to their construction. They could be pressurized to 1,350 psi and make 22.7 knots at 400 metres. They lost 86 pounds of pressure per day on average.[55]

1886

4,019 runs made, 79% successfully. A reduction in target size to one third the prior standard accounts for the shortfall.[56]

1887

4,363 runs made, 84.5% successfully.[57]

1888

5,228 runs made, 82.9% successfully.[58]

120 14-in Mark VIII torpedoes were ordered. Some "Leeds torpedoes" may also have come from G&B.[59]

1889

6,162 runs made, 88.9% successfully.[60]

200 14-in Mark VIII torpedoes were ordered. Some or all of these may have been "Leeds" torpedoes.[61]

1890

7,088 runs made, 88.6% successfully.[63]

Control of the torpedo factory at Woolwich was transferred from the Royal Laboratory to the Royal Gun Factory. Markings of the torpedoes was therefore to change to R.G.F. from R.L..[64]

230 14-in Mark VIII torpedoes under manufacture were adjusted at the Horsea range and were making 26 knots in 59 degree water. Individual torpedoes were requiring, on average, 16 test runs to be passed.[65]

Alterations in the Mark VIIIs were retrofitted to those already made, back to number 1579, but no change in name accompanied the eleven alterations listed.[66]

Conversion of R.L. torpedoes Marks IV, V and VI was underway, with 3, 44 and 118 torpedoes of each Mark having been completed, respectively. Most of these were sent to the Malta range for adjustment, and Mediterranean ships with these Marks of torpedo were exchanging their supplies as opportunity allowed.[67]

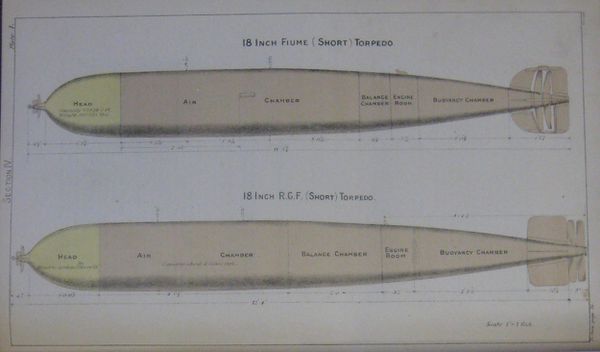

"Long" and "short" 18-in torpedoes were being evaluated from R.G.F. and Fiume. A single example was run 400 times to test different propellor designs. The "short" models were to weigh 850 pounds and be 11.5 feet long. An R.G.F. article proved lighter, at 831 pounds. A second design was 12 feet 4 inches long and 850 pounds, and had a larger engine giving greater stability. As this still worked in the experimental tube, two more of these were ordered.[68]

A delivery of 150 18-in torpedoes from Fiume had been completed, two of which were "short" were found to do 28.44 knots to 800 metres in 65 degree water.[69]

The double Mark VII B. tubes ere designed for the Sharpshooter class were tried in Seagull and reported on.[70][71]

Designs for collision heads were tested on a Mark IV Fiume and a Mark VII* R.L. torpedo against Resistance.[72]

14-in Mark VIII torpedoes were compared to examples built by G. & B. in different water temperatures, yielding similar results with perhaps a small edge to Leeds, as the 26 knots both delivered on average was in 57 degree water for Leeeds and 59 degree water for the R.L. torpedo. The R.L. torpedoes degraded from 26.4 knots in 67 degree water to 25.05 knots in 44 degree water.[73]

Trials of a new Whitehead submerged tube was undertaken in Vulcan, comparing it to a Service design. The Whitehead design placed less strain on the torpedo and its bar did not need to be deployed well before firing, but it was 21% heavier at 11.5 tons for the 18-in model, longer, and 477% more expensive at 4200£. The Service pattern would continue to be chosen.[74]

1891

6638 runs are made, 90.0% successfully.[75]

90 14-in Mark VIII torpedoes fitted for above-water fire from the previous year were adjusted and made 25.87 knots in 62 degree water. The 45 for submerged fire made 24.18 knots in 58 degree water. There were no further orders for 14-in torpedoes.[76]

50 Mark VIII torpedoes from Greenwood and Batley were ordered, and were to be completed by the next running season, indicating an increased capacity at G. & B. from the 20/year yield previously possible.[77]

Conversion of R.L. Marks IV, V and VI continued, with totals completed reaching 9, 99 and 146, respectively.[78]

G. & B. were given 72 Mark IV Leeds torpedoes for conversion, and the first 32 were completed with side lugs and achieved 20.3 knots in 43 degree water.[79]

An order for 100 new-design long 18-in Fiume torpedoes was being prepared for the coming fiscal year, 18 improvements being indicated over the previous order.[80]

1892

6339 runs, 91.3% good shots.[81]

No orders for 14-in torpedoes given to R.G.F., but two experimental 14-in Mark IX torpedoes were made to sound out a new design,[82] but twenty-five new 14-in torpedoes similar to Mark VIII were ordered from G&B.[83]

The 14-in torpedoes R.L. Marks I-III and Fiume Marks I-II were deemed obsolete.[84]

Conversion of Marks IV, V and VI R.L. continue, with 50, 157 and 187 converted or under conversion, respectively. 25 Mark VIII torpedoes ordered from G&B – last year's 50 were averaging 25.2 knots in 55 degree water, averaging 43 runs each for acceptance. 78 Mark IV Leeds torpedoes converted by G&B were passed, making barely 21 knots in 47 degree water.[85]

1893

The first 50 14-in Mark VIII torpedoes of an order for 100 have been manufactured. Their design is slightly different than prior Mark VIIIs.[86]

The 14-in Mark IX torpedoes are still under trial, and variant heads and after bodies were still being tested. A cissoid head gave a half knot better speed than a Mark VIII head or a bluff head.[87]

The 14-in Fiume Mark V torpedo was considered inferior in testing to 14-in Mark IX torpedo in speed, simplicity of working parts and quickness to recover from a dive, though its 90 pound warhead was less than the Fiume's 100.[88]

All 16-in torpedoes were to be broken up except for those in Agincourt and six spares. Similarly, those 14-in torpedoes older than Mark IV* were to be replaced when newer units became available.[89]

1894

Henceforth, the 14-in Mark IX torpedo was to be the only type for continued manufacture, and to procure the 18-in Mark II torpedo and not the 18-in Fiume Mark II torpedo. The short type was to be discontinued.[90]

Torpedoes ordered, made or delivered this year were

- 18-in R.G.F. Mark II (long)

- 18-in R.G.F. (short)

- 18-in Fiume Mark II (long)

- 18-in Fiume (short)

- 14-in Mark VIII. 100 passed, all with 3-bladed props. 50 with stop guards and 50 with rounded horizontal fins for better passing through nets.[91]

- 14-in Mark IX

There was dissatisfaction with Fiume torpedoes this year. Some were found not to have interchangeable heads owing to imprecise manufacture, especially those made in Portland.[92]

there were 2016 runs from tubes, producing 1937 hits with 45 lost shots and 34 failures. Dropping gear runs were 864 with 822 hits, 26 lost shots and 16 failures. This equated to a success rate of almost 96%, clearly indicating a lax criterion for evaluation.[93]

1895

The 1895-1896 order was to be:[94]

- 180 14-in Mark IX torpedoes: 150 from Whitehead and 30 from Woolwich.

- 248 18-in Mark IV torpedoes: 60 from Whitehead and 188 from Woolwich

These torpedoes were providing great satisfaction over previous designs.

The 18-in torpedoes would be passed at 800 yards range, suggesting perhaps an extension of the Horsea range.[95]

The Majestic and Magnificent are the only ships provided these torpedoes in 1895, each with seventeen 18-in torpedoes and five 14-in for their boats.[96]

1896

The 1896-97 order was to be:[97]

- 270 14-in Mark IX torpedoes: 120 from Woolwich and 150 by Whitehead, Weymouth

- 275 18-in Mark IV torpedoes: 215 from Woolwich and 60 at Weymouth

G. & B. received an order to make 50 of the 18-in Mark IV for the coming year.[98]

A new design of 14-in torpedo was being considered to address engine room weakness in the Mark IX, and to increase range and buoyancy. [99]

Reports of the first gyroscope, a Petrovich model successfully trialled and adopted in Whitehead 14- and 18-in torpedoes was supplied. Whitehead was also fitting these in R.L. [sic] 14- and 18-in torpedoes to propose that trials take place in Weymouth.Austria, Germany, Sweden, Norway, Denmark, Holland, Argentina and America were already reported as having signed royalty agreements of 30£ on each gyroscope made for 15 years coming. Other nations were making similar arrangements.[100]

1897

Manufacturing as follows:[101]

- 80 14-in Mark IX torpedoes are ordered and under manufacture at Woolwich.

- 330 18-in Mark IV torpedoes under manufacture, 180 from Woolwich, 100 by Whitehead & Co., and 50 by Greenwood and Batley, at Leeds.

1898

The orders for 1898-99 are:[102]

- 300 18-in Mark IV torpedoes: 150 from Woolwich, 100 from Whitehead, Weymouth and 50 from G&B

- 50 14-in Mark X torpedoes (a new design) from Woolwich

- 100 14-in Weymouth Mark I torpedoes (a new design) from Whitehead, Weymouth.

The 14-in Mark X torpedoes were likely to go to new battleships and first-class cruisers for use in their boats' dropping gear.

The new Weymouth torpedoes would go to torpedo boats and complete the replacement of Fiume Mark I* torpedoes and replace some of the remaining Fiume Mark IVs.

50 of the 18-in Mark IVs and all the 14-in torpedoes from this order would receive gyroscopes (Weymouth pattern).

It was determined by trials in 1897 and 1898 that four-bladed propellors were better than the two- and three-bladed models in use. 14-in torpedoes should use pitches increasing from 31 to 41 inches, and 18-in torpedoes with 35 to 45 inches. Newly-made replacement propellors for 14-in R.L. Marks VII, VII* and VIII, 14-in R.G.F. Marks VII and IX, and 18-in R.G.F. Marks I-IV were to be these new 4-bladed ones. 14-in R.L. Marks VII*, VIII and R.G.F. Mark VIII weapons appropriated to torpedo boats (only) would be given these new props when the torpedoes were next reset. The 14-in R.G.F. Mark IX and 18-in R.G.F. Marks I-IV would be re-propped when an entire ship's store of torpedoes came in for resettings (as when paying off).[103]

1899

7,510 runs produced 96.98% good runs in the year ending June 30th.[104]

The orders for 1899-1900 are:[105]

- 235 18-in Mark IV torpedoes: 85 from Woolwich, 100 from Whitehead, Weymouth and 50 from G&B

- 130 14-in Mark X torpedoes from Woolwich

- 100 14-in Weymouth Mark I torpedoes from Whitehead, Weymouth.

52 18-in Weymouth Mark I torpedoes and 33 14-in Mark X torpedoes were issued. 300 more gyros were ordered and all delivered. Vernon and a list of 25 ships as well as the T.B.s at Malta, Gibraltar, Devonport and Chatham had been equipped. Furthermore, plans to equip 23 destroyers at Portsmouth, 17 at Chatham and 22 at Devonport.[106]

1900

The orders for 1900-01 were:[107]

- 185 18-in Mark IV torpedoes: 45 from Woolwich, 115 from Whitehead, Weymouth and 25 from G&B

- 200 14-in Mark X torpedoes from Woolwich

- 85 14-in Weymouth Mark I torpedoes from Whitehead, Weymouth.

All these torpedoes would be completed with gyroscopes.[108]

In addition, Woolwich had added gyros to 80 14-in Mark VIII torpedoes, Portsmouth to 125 more, Chatham to 25 18-in Mark IV torpedoes, Devonport to 25 more, and Whitehead to 100 more.[109]

1901

The orders for 1901-02 were:[110]

- 255 18-in Mark IV torpedoes: 5 from Woolwich, 210 from Whitehead and 50 from G&B

- 25 18-in Mark V torpedoes from Woolwich

- 110 (140?) 14-in Mark X torpedoes from Woolwich

- 85 14-in Weymouth Mark I torpedoes from Whitehead, Weymouth.

The programme to add gyros to older torpedos continued apace on 14-in Mark VIII torpedoes, 14-in Mark IX torpedoes, and 18-in R.G.F. Marks I-IV: Woolwich had added gyros to 150, Portsmouth to 150, Chatham to 50, Devonport to 50, and Whitehead to 100 more.[111]

1902

The orders for 1902-03 were:[112]

- 68 18-in Mark V* torpedoes, H.B. type from Whitehead

- 65 18-in Mark V* torpedoes, H.B. type from Woolwich

- 82 18-in Mark V* torpedoes, S.L. from Whitehead

- 100 14-in Mark X* torpedoes and 14-in Mark XI torpedoes

It was proposed and decided to withdraw all 14-in R.L. and R.G.F. torpedoes prior to Mark VIII and also any individual R.G.F. Marks I-III deemed unworthy of being fitted with gyroscopes. The withdrawal was to be spread over years 1903-04 and 1904-05, retaining only a proportion of torpedoes as would be desired for live exercise. Order were issued to break up all 14-in Marks V* and VI* and all 18-in Shorts that have been replaced by later types, with 14-in Mark VII* and 18-in Fiume Mark I to be retained for live fire. Fitting gyros to 18-in Marks I-II and 18-in Fiume Mark II would stop, but those already fitted would be retained.[113]

1903

The orders for 1903-04 were:[114]

- 100 18-in Mark V torpedoes

- 25 18-in Mark V torpedoes

- 51 14-in Mark X torpedoes

- 59 14-in Mark X* torpedoes

The programme to add gyros to older torpedos continued apace on 14-in Mark VIII torpedoes, 14-in Mark IX torpedoes, 18-in R.G.F. Marks I-IV and now also 18-in Fiume Mark II torpedoeses: Woolwich had added gyros to 200, Portsmouth to 50, Chatham to 25, Devonport to 25, Whitehead to 100, and G & B to 100 more.[115]

All future 14-in torpedoes up to Mark X will be adjusted for 800 yards, Mark X* and XI for 1,000 yards. All 18-in H.B. torpedoes will be adjusted for 1,500 yards and 18-in S.L torpedoes for 1,000 and 1,500 yards.[116]

1904

The orders for FY 1904-05 were to be a mix of 458 14- and 18-in torpedoes:[117]

| Type | Ordered |

|---|---|

| 14-in Mark XI torpedoes | 77 |

| 18-in Mark V* torpedoes H.B. | 106 |

| 18-in Mark V* torpedoes S.L. | 175 |

| 18-in Fiume Mark III torpedoes H.B. | 100 |

5.9% of all gyro torpedoes fired were lost shots. Of those, 41.5% were due to gyros, 31.9% due to torpedo, and 26.6% due to director or other adjustments being wrong. Non-gyro torpedo failures were, perhaps predictably, most often due to a curved run for undiagnosed reasons, but the total lost shot score was nearly the same at 6.0%[118]

1905

The orders for FY 1905-06 were to be a mix of 607 14- and 18-in torpedoes:[119]

| Type | Ordered |

|---|---|

| 14-in Mark XI torpedoes H.B. | 54 |

| 18-in Mark V* torpedoes H.B. | 111 |

| 18-in Mark V* torpedoes S.L.L.R. | 146 |

| 18-in Mark V* torpedoes S.L.S.R. | 11 |

| 18-in Fiume Mark III** torpedoes H.B. | 100 |

| 18-in Fiume Mark III* torpedoes S.L.L.R. | 22 |

| 18-in Fiume Mark III* torpedoes S.L.S.R. | 114 |

| 18-in Mark VI torpedoes H.B. | 24 |

| 18-in Mark VI torpedoes S.L.L.R. | 25 |

In order to meet demand, Messrs Greenwood and Batley were to manufacture 51 of the 18-in Mark V* torpedoes with side lugs. 6.1% of torpedoes fired in 1905-05 were lost shots, of which 40.3% were due to the tube, 35.7% to the gyro and gear, and 24.0% to bad adjustments.[120]

In fleet practice, 237 shots were fired for 31.2% hits. Some leading reported reasons were enemy evasion (35%), estimates of enemy speed (18%) and range (3.1%).[121]

1906

The orders for FY 1906-07 were to be:[122]

| Type | Ordered |

|---|---|

| 18-in Mark VI torpedoes H.B. | 31 |

| 18-in Mark VI* torpedoes S.L.L.R. | 336 |

| 18-in Mark VI* torpedoes S.L.S.R. | |

| 18-in Fiume Mark III* torpedoes H.B. | 144 |

| 18-in Fiume Mark III* torpedoes S.L.L.R. | 40 |

| 18-in Fiume Mark III* torpedoes S.L.S.R. |

5.24% of torpedoes fired in 1905-6 failed to hit their target. The faults were attributable as follows: 14.2% due to torpedo, 17.7% due to tube, 7.2% personal errors, 18% to poor director setting, and 10.4% to gyro mechanism failures and 28% to gyro due to maintenance and test.[123] When directors were poorly set, 66% of the cases were attributed to errors in range estimate and 15% of them to errors in estimating target speed. In fleet practice, 52 hits were obtained from 166 firings, with most misses being due to a bad estimate of enemy speed (34%). Enemy evasion (10%) and range estimation (8%) were also common.[124]

1907

When omissions were corrected the following year, orders for FY 1907-08 were:[125][126]

| Torpedoes Ordered | |

|---|---|

| 18-in Mark VI* torpedoes H.B. | 7 |

| 18-in Mark VI* torpedoes S.L. | 74 |

| 18-in Fiume Mark III* torpedoes | 24 |

| Cold Torpedoes Given Heaters (H.) | |

| 18-in Mark VII torpedoes S.L. | 6 |

| 18-in Mark VI* torpedoes H.B. | 17 |

| 18-in Mark VI* torpedoes S.L. | 12 |

5.53% of torpedoes fired in 1906-7 failed to hit their target. The faults were attributable as follows: 28.2% due to torpedo, 4.9% due to tube, 14% neglect of tests, 19.3% to poor director setting, and 35.5% to gyro failures.[127] When directors were poorly set, half the cases were attributed to errors in range estimate and an eighth of them to errors in estimating target speed. Why the range was needed at all (other than to assure it was within range) is unclear. In Fleet Practice, 40.1% of torpedoes fired under conditions that permitted the target to manœuvre were hits. This was an improvement from 31.3% over the previous 12 months.[128]

1908

A single short tube cost 350-400 pounds, weighing 3136 pounds. The long tubes weighed 3138 pounds.[129] The work for 1908-09 was as follows:[130]

| Torpedoes Ordered | |

|---|---|

| 18-in Mark VII* torpedoes S.L. | 40 |

| 18-in Mark VII torpedoes S.L. | 79 |

| 18-in Weymouth Mark I torpedoes S.L. | 20 |

| Cold Torpedoes Given Heaters (H.) | |

| 18-in Fiume Mark III** torpedoes H.B. | 38 |

| 18-in Fiume Mark III** torpedoes S.L. | 12 |

| 18-in Mark VI* torpedoes H.B. | 17 |

1909

| Torpedoes Ordered[131] | |

|---|---|

| 18-in Mark VII* torpedoes | 58 |

| 18-in Mark VII* torpedoes, w/o heaters, by Whitehead |

60 |

| 21-in Mark I torpedoes S.L. | 66 |

| 21-in Mark II torpedoes H.B. | 4 |

| 21-in Mark II torpedoes, w/o heaters, by Whitehead |

146 |

| Cold Torpedoes Given Heaters (H.) | |

| 18-in Mark VII** torpedoes H.B. | 53 |

| 18-in Mark VII** torpedoes S.L. | 120 |

| 18-in Mark VII** torpedoes S.L. | 23 |

1910

| Type | Ordered | Delivered thru Nov 1910 | ||

|---|---|---|---|---|

| R.G.F. | W. & Co. | R.G.F. | W. & Co. | |

| 18-in Marks VII & VII* | 183 | 60 | 115 | 19 |

| 21-in Mark I torpedoes | 106 | — | 49 | — |

| 21-in Mark II torpedoes | 142 | 146 | Nil | Nil |

1911

| Type | Ordered | Delivered thru Nov 1911 | ||

|---|---|---|---|---|

| R.G.F. | W. & Co. | R.G.F. | W. & Co. | |

| 18-in Mark VII* torpedoes | 183 | 97 | 5 | 8 |

| 21-in Mark I torpedoes | 106 | — | 86 | — |

| 21-in Mark II torpedoes | 287 | 401 | 75 | 105 |

| 18-in Weymouth Mark I* torpedoes | — | 84 | — | — |

1912

Double tube mountings were first installed in the L class destroyers.[132]

| Type | Ordered | Delivered thru Nov 1912 | ||

|---|---|---|---|---|

| R.N.T.F. | W. & Co. | R.N.T.F. | W. & Co. | |

| 18-in VII* and VII** | 25 | 100 | 5 | 8 |

| 18-in Weymouth Mark I* torpedoes | — | 118 | — | — |

| Marks I & I* | 56 | — | 35 | — |

| Marks I & II* | 208 | 280 | 80 | 78 |

1913

| Type | Ordered | Delivered thru Nov 1913 | ||

|---|---|---|---|---|

| R.N.T.F. | W. & Co. | R.N.T.F. | W. & Co. | |

| 18-in Mark VII* and VII** | 77 | 166 | 8 | 49 |

| 18-in Mark VIII | 2 | — | 2 | — |

| 18-in Weymouth Mark I* torpedoes | — | 34 | — | 9 |

| 21-in Mark I* torpedoes | 16 | — | 7 | — |

| 21-in Mark II* torpedoes | 316 | 394 | 97 | 202 |

Two of the new 18-in Mark VIII R.N.T.F. torpedoes were under trial in 1913. They were intended for use by submarines, sporting 320 lbs TNT (total head weight without pistol: 413 lbs), stamped 41 knots to 1500 yds and 29 knots to 3500 yards when charged to 1600 psi. Depth gear was Service type with double hydrostatic valves. The 18-in Mark IX torpedo was awaiting design, pending trials with Ulan depth gear and double reducers. 18-in Weymouth Mark I* were noted as being described in T. Orders Nos. 48 and 66 of July and September, 1913.[133]

1914

The 18-in Marks VI**, VII*** and VIII G.S. and 21-in Marks II** and III were new this year. At the start of the war, all 21-in Weymouth torpedoes in England were purchased: one Weymouth Mark III*, 24 IIs intended for Japan and 2 IIIs intended for Turkey. One Mark III* and six Mark II were given to Broke and ten Mark II to Erin and eight Mark II and two Mark III to Agincourt.[134]

All new gyros to be produced were to have 5 degree angling on short release, with priority of supply being to new battleships being built.[135]

1915

During GF practice running from June-August, 9.9% of torpedoes were lost shots, versus 19.73% in 1913, the last year recorded.[136]

A complete list of torpedoes in use is provided.[137]

1916

- 18-in Mark VII**** torpedoes

- 18-in Mark IX torpedoes

- 21-in Mark II**** torpedoes

- 21-in Mark II***** torpedoes

- 21-in Mark IV torpedoes

Extreme Range (E.R.) torpedoes were to be supplied to the following plan:[138]

- two 21-in Mark II***** or IV H.B. or S.L. to be supplied to each battleship, battle cruiser, or light cruiser with 21-in tubes.

- Complete outfit of above types to each T.B.D completed after 31 October 1916.

- 21-in Mark II-II*** E.R.3 H.B. or S.L. All existing 21-in torpedoes to be converted to this E.R. 3 type, giving all vessels torpedoes which can be used as E.R. when needed

- 18-in Mark VII**-VI**** E.R.3 H.B. or S.L. All existing Mark VII torpedoes in all vessels to be converted to E.R. 3 standard

The first E.R. torpedoes attained this feature by means that did not permit readily switching them to another setting and it was estimated that fully 25% of the torpedoes so altered would fail to meet the mark, but this expedient means was seen as excusable in the interim, and the estimate of failures was later viewed as too alarmist. Soon thereafter, the 21-in II***** and IV were to incoporate three-speed generators, to overcome the limitation on quick selection of an E.R. mode.[139]

A process of replacing converted heaters and cold torpedoes by 18-in VII** to VII**** in the later BBs BCs and LCs is proceeding as torpedoes become available. Armoured cruisers in home waters have been supplied with six or nine 18-in VII** to VII**** depending on whether they have two or four tubes. Later subs are being given at least some of these for their bow tubes. In earlier subs, 18-in VIII is replacing V*, which again replaces Mark IV still carried in some of the earliest boats.[140]

The Mark VII****'s differences from VII*** are noted in ARTS 1916. They had a tail of H.B. 1 - S.L. 1 type and swappable warheads with other Marks VII.[141]

The Mark IX was lightweight for use from seaplanes with heater engine of VI*** H. type, 12 feet 10 inches overall. 170 lbs Amatol, 29 knots at 2000 yards, total weight 996 lbs, Buoyancy at total weight approx -45.5 pounds, air vessel 5 cubic feet and 1500 psi, 39 lbs air, 18.9 lbs water in 282 fl oz bottle, 2.1 lbs fuel in 42 fl oz bottle, engine oil 27.5 oz bottle.[142]

The 21-in Mark II****'s differences from II*** are noted in ARTS 1916. They had a tail of H.B. 1 - S.L. 1 type and swappable warheads with other Marks II.[143]

The 21-in Mark II*****'s differences from II**** are noted in ARTS 1916. They used 3 ozs oil per 1000 yards at 19 knot setting and 2 ozs per 1000 yards at 24 knot. Ranges not marked on shells.[144]

The RNTF 21-in Mark IV's details are covered. These weapons were more finely trimmable to avoid surface runs. Tested to 2500 psi, but action use at 2650 psi -- handle with care! A trim weight was added aft when warhead on, giving 0.75 lbs negative buoyancy when empty. Original warhead IVA of 450 pounds TNT was 2.3 inches longer than for 21-in II-II*****, but new IVB with 500 pounds TNT will increase length by another 7.5 inches. H.B. and S.L. settings at 2650 psi were 44.5 knots to 4500 yards, 25 knots to 15,000 yards, 21 knots to 18,000 yards. At 2500 psi ranges would be 4,200, 14,000 and 17,000 yards. The torpedo runs about 1 to 1.5 knots faster for three quarters of the max range.[145]

18-in Mark IV H was experimented with in 1916, sharing air flasks with Mark IV torpedoes and using Mark VI* H engine. Proposed wt explosives 250 lbs Amatol. Expected 35 knots to 1,500 [146]

21-in Weymouth Mark III were made to Turkish order and supplied for stern tube of Agincourt. They are to be re-ranged to 21 knots and given to Erin and Agincourt for broadside use. [147]

18-in F III** V.B. to be supplied to Gorgon and Glatton for their 18-in Elswick submerged tubes. S.R. 26.25 knots to 2,000, LRT 19 knots to 4,000 yards. [148]

New tail fittings[149] adopted for new fish, including 18-in VII****, such fish being known as H.B. 1 and S.L. 1 The result is reduced chances of fouling in tubes. [150]

21-in warheads. Mark IV A had 400 pounds, new Mark IV B has 500 pounds. Usable in all 21-in tubes as they are all 23 feet. A pioneer would project 4 inches from the tube and so new 21 tubes are being made to 23.5 feet. [151]

14-in heads - approval for 14-in Mark IX and Weymouth Mark I heads to be filled w/ Amatol. All torpedoes but 18-in F II and RGF I* to III* will eventually follow. Weight for charges in 14-in torps is IX 110 lbs, Weymouth I 110, X/X* 115 lbs, XI 120 lbs. AR 1915 p 39 lists others, this figure corrects X/X* weight thereat. [152]

Introduction of E 2 pioneers - experiments show torps with fixed blade pioneers easily pene harbor nets w large diam grommets and gauge 9 wire or below whereas the E 1 type does not penetrate with its sliding chisel-edged blades. One E 2 pattern pioneer w fixed blades will be supplied to each T.B.D. or sub with 21-in torps in lieu of one of her existing E 1 pioneers (TO 159/1916). [153]

Experiments to force surface-running from A.W. tubes for short-range fire between T.B.D.s at night by fitting hydroplanes w 20 deg up angle at torp head proved workable at slow and med speeds but not high speed.[154]

An increase of 150 psi was found to increase high speed range by 300 yards and medium and E.R. ranges by 1,000 yards. 21-in IV now 2650 "for action only" and 21-in torps formerly 2350 and 2200 psi are also to have 150 psi added "for action only". Safety factor against bursting reduced from 2.25 to 2.11 is accepted as war risk. The extra 150 is to be topped up before heading to sea. 18-in Marks VII to VII*** are not to receive added pressure.[155]

New gyroscopes able to support larger gyro angles were created for high speed ships whose deflection might be as much as 40 deg, to allow gyro angles over 90 deg esp for subs, and for gyro control gear. [156]

Subs wanted and had tested: new 3.33 degree gyro angle increments, another adaptation permitted 0.5 degree increments, and a third offering 1 degree increments. The first was judged not flexible enough for requirements, and the second required undesirable changes in gyroscopes. The third was taken although it abandoned the idea of a "positive lock" that had previously been insisted on. It was an utter failure. Two other plans, one permitting continuous angle setting and the second half degree increments up to 8 degrees were still under trial. In meantime, design of a 5-degree increment all-round gyro with removable stops at 70 degrees and a device permitted half degree increments up to 5 degrees either way to be installed before the gyro is fitted was being undertaken. [157]

Sandford Gyro Control Gear is being ordered for use on submarine torpedoes.[158]

Larger gyro rudders (1.3-in vs 1-in) needed for 21-in II**** and IV to produce steadier running and better direction at low speeds. Long Loch testing with 18-in VII**** E.R. showed the rudders not powerful enough at 19 knot setting. Wider ones will be fitted to all 18-in E.R. torpedoes [159]

Toward the end of 1916, Caton Engineering Company, Ltd. started supplying 18-in torpedoes. 21-in deliveries were to commence in 1918, with the quota being 15 torpedoes a week.[160]

From 1 October 1915 to 30 September 1916, practice runs of torpedoes fired from battleships, battlecruisers, cruisers and light cruisers yielded the following statistics describing their reliability. [161]

- of 542 21-in submerged fire torpedoes fired:

- 89.1% were "dangerous to enemy", and 80.4% were "dangerous to enemy" AND "satisfactory" runs.

- 10.8% of all shots were "lost shots": 2.8% were dangerous curves, 3.9% were cold runs, and the remainder various failures

- of 126 21-in above water torpedoes fired:

- 92.8% were "dangerous to enemy", and 82.5% were "dangerous to enemy" AND "satisfactory" runs.

- 7.2% of all shots were "lost shots": 2.4% were dangerous curves, 1.6% were cold runs, and the remainder various failures

By comparison, the T.B.Ds. managed the following over a half year:

- of 804 torpedoes of various types fired:

- 86% were "dangerous to enemy", and 82.3% were "dangerous to enemy" AND "satisfactory" runs.

- 14% of all shots were "lost shots": 3.2% were dangerous curves, 3.7% of heater torpedo shots were cold runs, and the remainder various failures

It was noted that 21-in above-water torpedoes fired from light cruisers was the most reliably dangerous to the enemy: 92.8%.

1917

Triple tube mountings were first installed in the W class destroyers.[162]

The following torpedoes and settings were available (knots/yds range -- torpedoes either had a 44.5 or 35 knot high speed setting).[163]

- 21-in Mark IV*, 44.5/4500 or 35/6000 (high speed), 29/11000 or 25/15000 (medium speed), 21/18000 (E.R.)

- 21-in Mark IV, 44.5/4500 or 35/6000 (high speed), 25/15000 (medium speed), 21/18000 (E.R.)

- 21-in Mark II*****, 44.5/4500 or 35/6000 (high speed), 24/15000 (medium speed), 19/18000 (E.R.)

- 21-in Mark II**-II****, 44.5/4500 or 35/6000 (high speed), 23/15000 (medium speed), 18/18000 (E.R.)

- 21-in Mark II=II*, 44.5/4200 or 35/6000 (high speed), 23/14000 (medium speed), 18/17000 (E.R.)

Speed limits on firing submerged tubes were adopted:[164]

- 21-in Mark II**** – IV* : no limit

- 21-in II***, strengthened : 27 knots

- 21-in II – II*** : 24 knots

- 18-in : no limit

A new Deep Running torpedo (D.R.) design with special hydrostatic valves was created in 1917, permitting depths of 8 to 40 feet, as 22 feet was seen as insufficient for use against submerged submarines. At the same time, a circling torpedo (D.R.C.) that ran at 4-5 times its set depth by virtue of a special valve disc.[165]

1918

British destroyers employed in hunting submarines were to keep torpedoes set to 23 feet running depth ready for immediate use against submarines encountered at periscope depth. A minimum range of 200 yards was considered reasonable, to permit the torpedoes to find their depth, and hits beyond 600 yards range were considered unlikely. A target speed of 5 knots was to be presumed, and torpedoes were to be fired singly. It is interesting to note that this terminology implies continued use of Torpedo Directors rather than Torpedo Deflection Sights. This is noted as being from "R.A. H.F. T. of I. No 20.", which might mean Rear-Admiral Tyrwhitt of the Harwich Force.[166]

Dates of Service

The information in the table below is coarse, as I did not generally record Section III of the ARTS. The dates noted for "first mention" generally alludes to their presence in Torpedo Drill Book (1905, 1908, 1912, 1914 consulted) or mention in ARTS 1917-1918, as I did capture some torpedo data from these editions.

14-in torpedoes

| Mark | Type/Manufacturer | Hot/Cold | Warheads | First mention | Last mention | Brackets | Notes |

|---|---|---|---|---|---|---|---|

| VIII | R.L. | Cold | 1905 | 1908 | Obsoleted in 1911[167] | ||

| IX | R.G.F., W. & Co., G. & B. |

Cold | 1905 | 1914 | 180/326 broken up 1918[168] | ||

| X | Cold | 1905 | 1914 | 120/421 broken up 1918[168] | |||

| X* | Cold | 1905 | 1914 | 20/85 broken up 1918[168] | |||

| XI | Cold | 1905 | 1914 | 10/129 broken up 1918[168] | |||

| I | Weymouth | Cold | 1905 | 1914 | 25/246 broken up 1918[168] |

18-in torpedoes

| Mark | Type/Manufacturer | Hot/Cold | Warheads | First mention | Last mention | Brackets | Notes |

|---|---|---|---|---|---|---|---|

| I | R.N.T.F., R.G.F., W. & Co., G. & B. |

Cold | ? | ? | H.B & S.L.? | 26/86 broken up 1918[168] | |

| I* | Cold | 1905 | 1914 | H.B & S.L. | |||

| II | Cold | ? | ? | H.B & S.L.? | 12/33 broken up 1918[168] | ||

| II* | Cold | 1905 | 1914 | H.B & S.L. | |||

| III | Cold | 1905 | 1914 | S.L. | 12/40 broken up 1918[168] | ||

| IV | Cold | 1905 | 1914 | H.B & S.L. | 30/1155 H.B. models broken up 1918[168] | ||

| IV H | Heat | 1916 | H.B & S.L. | 30/1155 H.B. models broken up 1918[168] Uses VI* H engine. 250 lbs amatol, projected 1500 @ 35.[169] | |||

| V | Cold | 1905 | 1914 | H.B & S.L. | 10/120 broken up 1918[168] | ||

| V* | Cold | 1905 | 1914 | H.B & S.L. | |||

| V* G.S. | Cold | 1914 | G.S. or bare | ||||

| VI | Cold | 1911 | 1914 | H.B & S.L. | |||

| VI G.S. | Cold | 1914 | G.S. or bare | ||||

| VI* | Cold | 1911 | 1914 | H.B & S.L. | |||

| VI*H. | Heat | 1911 | 1914 | H.B & S.L. | |||

| VI**H. | Heat | 1911 | 1914 | H.B & S.L. | |||

| VI***H. | Heat | 1911 | 1914 | H.B & S.L. | |||

| VII | Heat | 1911 | 1914 | H.B & S.L. | |||

| VII S. | 1918 | H.B & S.L. | |||||

| VII* | Heat | 1911 | 1914 | H.B & S.L./subs | |||

| VII** | Heat | 1911 | 1914 | H.B & S.L./subs | |||

| VII*** | 1914 | 1914 | H.B & S.L./subs | ||||

| VII**** | 1916[170] | H.B & S.L./subs | |||||

| VII***** | new in 1917[171] | H.B & S.L./subs | |||||

| VIII | 1918 | H.B & S.L.? | |||||

| VIII R.A.F. | 1918 | ||||||

| VIII S. | 1918 | also cmb | |||||

| VIII* | new in 1915[172] | H.B & S.L.?/subs/air/cmb | |||||

| IX | 1916[173] | air | |||||

| II | Fiume | Cold | 1905 | 1914 | S.L. | 203/203 broken up 1918[168] | |

| III | Cold | 1905 | 1914 | H.B. | 32/74 broken up 1918[168] | ||

| III* | Cold | 1908 | 1914 | H.B & S.L. | 30/102 broken up 1918[168] | ||

| III** | Cold | 1908 | 1914 | H.B & S.L. & V.B. | 30/191 broken up 1918[168] V.B. for Gorgon and Glatton: 2000 yds @ 26.25 knots, 4000 @ 19[174] | ||

| III**H. | Heat | 1912 | 1914 | H.B & S.L. | 40/40 broken up 1918[168] | ||

| I | Weymouth | Heat | 1905 | 1914 | S.L. | ||

| I* | Heat | 1911 | 1914 | S.L. |

21-in torpedoes

| Mark | Type/Manufacturer | Hot/Cold | Warheads | First mention | Last mention | Brackets | Notes |

|---|---|---|---|---|---|---|---|

| I | R.N.T.F., R.G.F., W. & Co. |

Heat | 1911 | 1914 | S.L. | none manufactured for Service[175] | |

| I* | Heat | 1911 | 1914 | S.L. | |||

| II | Heat | 1911 | 1914 | H.B & S.L. | |||

| II* | Heat | 1911 | 1914 | H.B & S.L. | |||

| II** | 1914 | 1914 | H.B & S.L. | ||||

| II*** | 1914 | 1914 | H.B & S.L. | ||||

| II**** | 1916[176] | H.B & S.L. | |||||

| II***** | early Nov 1916[177] | H.B & S.L. | See ARTS 1916, p. 40 | ||||

| IV | issued Feb 1917[178] | H.B & S.L. | |||||

| IV* | new in 1917[171] | H.B & S.L. | |||||

| IV* S.[179] | 1918 | H.B & S.L.? | |||||

| V | new in 1918[179] | ||||||

| VI | 1918 | ||||||

| II | Weymouth | 1914 | 1914 | ||||

| III | 1914 | 1916 | Made for Turkey for stern tube Agincourt, to be re-ranged @ 21 knots for broadside Erin and Agincourt[180] | ||||

| III* | 1914 | 1914 |

See Also

Footnotes

- ↑ Annual Report of the Torpedo School, 1890. p. 19.

- ↑ Torpedo Manual, Vol. III, 1909. p. 5.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 10.

- ↑ Acklom Service Record. The National Archives. ADM 196/43/238. f. 262.

- ↑ Acklom Service Record. The National Archives. ADM 196/43/238. f. 262.

- ↑ Ball Service Record. The National Archives. ADM 196/45/67. f. 67.

- ↑ Ball Service Record. The National Archives. ADM 196/45/67. f. 67.

- ↑ Annual Report of the Torpedo School, 1913. p. 12.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 11.

- ↑ Annual Report of the Torpedo School, 1915. p. 38.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Torpedo Manual, Vol. III, 1909. pp. 3-4.

- ↑ Torpedo Manual, Vol. III, 1909. p. 5.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 9.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 10.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 11.

- ↑ Annual Report of the Torpedo School, 1915. p. 37,.

- ↑ Annual Report of the Torpedo School, 1916. pp. 43-44. (T. Os. 58, 135 of 1916).

- ↑ Annual Report of the Torpedo School, 1916. p. 44.

- ↑ Annual Report of the Torpedo School, 1916. pp. 44-45.

- ↑ Annual Report of the Torpedo School, 1916. p. 45.

- ↑ Annual Report of the Torpedo School, 1916. p. 45.

- ↑ Annual Report of the Torpedo School, 1916. p. 45. (T.Os. 56 and 66 of 1917).

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 9.

- ↑ Annual Report of the Torpedo School, 1913. Plate 10.

- ↑ Annual Report of the Torpedo School, 1900. pp. 36-9.

- ↑ Annual Report of the Torpedo School, 1900. pp. vi, 32.

- ↑ Annual Report of the Torpedo School, 1900. pp. 36, 39.

- ↑ There were rules of thumb for the sternward deflection torpedoes would have when fired from different ships at different torpedo tube training angles and own ship speed.[Citation needed]

- ↑ Annual Report of the Torpedo School, 1907. p. 30.

- ↑ Annual Report of the Torpedo School, 1911. p. 90. (D.N.O. 26th July 1911).

- ↑ Annual Report of the Torpedo School, 1911. p. iv.

- ↑ Annual Report of the Torpedo School, 1913. pp. 23-4. The "Type A" gear is illustrated in Plate 9, not reproduced here.

- ↑ Annual Report of the Torpedo School, 1914. pp. 27.

- ↑ Annual Report of the Torpedo School, 1916. p. 56.

- ↑ Annual Report of the Torpedo School, 1913. p. 25.

- ↑ Annual Report of the Torpedo School, 1882. p. 29.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1881. p. 23.

- ↑ Annual Report of the Torpedo School, 1881. pp27-8.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1882. p. 31.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1883. p. 24.

- ↑ Annual Report of the Torpedo School, 1884. p. 47.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1884. pp. 45-6, Plate 14.

- ↑ Annual Report of the Torpedo School, 1884. p. 46.

- ↑ Annual Report of the Torpedo School, 1884. p. 46, Plate 15.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1885. p. 13.

- ↑ Annual Report of the Torpedo School, 1885. p. 13.

- ↑ Annual Report of the Torpedo School, 1885. p. 13.

- ↑ Annual Report of the Torpedo School, 1885. p. 12.

- ↑ Annual Report of the Torpedo School, 1885. p. 13-4.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1890. p. 19, 22.

- ↑ Annual Report of the Torpedo School, 1890. p. 17.

- ↑ Annual Report of the Torpedo School, 1890. p. 19.

- ↑ Annual Report of the Torpedo School, 1890. Plate 1.

- ↑ Annual Report of the Torpedo School, 1891. p. 21.

- ↑ Annual Report of the Torpedo School, 1890. p. 19.

- ↑ Annual Report of the Torpedo School, 1890. p. 19.

- ↑ Annual Report of the Torpedo School, 1890. p. 19.

- ↑ Annual Report of the Torpedo School, 1890. p. 22.

- ↑ Annual Report of the Torpedo School, 1890. pp. 22-4.

- ↑ Annual Report of the Torpedo School, 1890. p. 29.

- ↑ Annual Report of the Torpedo School, 1888. p. 44.

- ↑ Annual Report of the Torpedo School, 1890. pp. 34-6.

- ↑ Annual Report of the Torpedo School, 1890. pp. 36-7.

- ↑ Annual Report of the Torpedo School, 1890. p. 38.

- ↑ Annual Report of the Torpedo School, 1890. p. 41-3.

- ↑ Annual Report of the Torpedo School, 1892. p. 18.

- ↑ Annual Report of the Torpedo School, 1891. p. 23.

- ↑ Annual Report of the Torpedo School, 1891. p. 23.

- ↑ Annual Report of the Torpedo School, 1891. p. 23.

- ↑ Annual Report of the Torpedo School, 1891. p. 23.

- ↑ Annual Report of the Torpedo School, 1891. pp. 25-6.

- ↑ Annual Report of the Torpedo School, 1893. p. 18.

- ↑ Annual Report of the Torpedo School, 1892. p. 20.

- ↑ Annual Report of the Torpedo School, 1892. p. viii.

- ↑ Annual Report of the Torpedo School, 1892. p. viii.

- ↑ Annual Report of the Torpedo School, 1892. p. 21.

- ↑ Annual Report of the Torpedo School, 1893. pp. 26-7.

- ↑ Annual Report of the Torpedo School, 1893. p. 28.

- ↑ Annual Report of the Torpedo School, 1893. p. 36.

- ↑ Annual Report of the Torpedo School, 1893. p. 36.

- ↑ Annual Report of the Torpedo School, 1894. p. viii.

- ↑ Annual Report of the Torpedo School, 1894. p. 56.

- ↑ Annual Report of the Torpedo School, 1894. p. 57.

- ↑ Annual Report of the Torpedo School, 1894. p. 95.

- ↑ Annual Report of the Torpedo School, 1895. p. viii.

- ↑ Annual Report of the Torpedo School, 1895. p. 27.

- ↑ Annual Report of the Torpedo School, 1895. p. viii.

- ↑ Annual Report of the Torpedo School, 1896. p. 18.

- ↑ Annual Report of the Torpedo School, 1896. p. vi.

- ↑ Annual Report of the Torpedo School, 1896. p. vii.

- ↑ Annual Report of the Torpedo School, 1896. pp. vii-viii, 77. Appendix H.

- ↑ Annual Report of the Torpedo School, 1897. p. 18.

- ↑ Annual Report of the Torpedo School, 1898. pp. vi-vii, 19.

- ↑ Annual Report of the Torpedo School, 1898. pp. 34-35.

- ↑ Annual Report of the Torpedo School, 1899. p. 58.

- ↑ Annual Report of the Torpedo School, 1899. p. 19.

- ↑ Annual Report of the Torpedo School, 1899. pp. 44-5.

- ↑ Annual Report of the Torpedo School, 1900. p. 32.

- ↑ Annual Report of the Torpedo School, 1900. p. vi.

- ↑ Annual Report of the Torpedo School, 1900. p. 32.

- ↑ Annual Report of the Torpedo School, 1901. p. 36.

- ↑ Annual Report of the Torpedo School, 1901. p. 36.

- ↑ Annual Report of the Torpedo School, 1902. p. 34.

- ↑ Annual Report of the Torpedo School, 1902. p. 34.

- ↑ Annual Report of the Torpedo School, 1903. p. 23.

- ↑ Annual Report of the Torpedo School, 1903. p. 23.

- ↑ Annual Report of the Torpedo School, 1902. p. v.

- ↑ Annual Report of the Torpedo School, 1904. p. 28.

- ↑ Annual Report of the Torpedo School, 1904. pp. 28-30.

- ↑ Annual Report of the Torpedo School, 1905. p. 12.

- ↑ Annual Report of the Torpedo School, 1905. p. 12.

- ↑ Annual Report of the Torpedo School, 1905. p. 14.

- ↑ Annual Report of the Torpedo School, 1906. p. 8.

- ↑ Annual Report of the Torpedo School, 1906. p. 8.

- ↑ Annual Report of the Torpedo School, 1906. p. 10.

- ↑ Annual Report of the Torpedo School, 1907. p. 8.

- ↑ Annual Report of the Torpedo School, 1908. p. 7.

- ↑ Annual Report of the Torpedo School, 1907. p. 8.

- ↑ Annual Report of the Torpedo School, 1907. pp. 10-11.

- ↑ March. British Destroyers. p. 513.

- ↑ Annual Report of the Torpedo School, 1908. p. 7.

- ↑ Annual Report of the Torpedo School, 1909. p. 7.

- ↑ March. British Destroyers. p. 513.

- ↑ Annual Report of the Torpedo School, 1913. p. 11.

- ↑ Annual Report of the Torpedo School, 1914. pp. 8-11.

- ↑ Annual Report of the Torpedo School, 1914. pp. 27.

- ↑ Annual Report of the Torpedo School, 1915. p. 25.

- ↑ Annual Report of the Torpedo School, 1915. pp. 31-33.

- ↑ Annual Report of the Torpedo School, 1916. p. 35.

- ↑ Annual Report of the Torpedo School, 1916. pp. 43-44.

- ↑ Annual Report of the Torpedo School, 1916. p. 36.

- ↑ Annual Report of the Torpedo School, 1916. p. 39. Much more minutiae thereat.

- ↑ Annual Report of the Torpedo School, 1916. p. 40. See also Plate 9.

- ↑ Annual Report of the Torpedo School, 1916. p. 40. Much more minutiae thereat.

- ↑ Annual Report of the Torpedo School, 1916. pp. 40-1. Much more minutiae thereat.

- ↑ Annual Report of the Torpedo School, 1916. p. 41. Much more minutiae thereat.

- ↑ Annual Report of the Torpedo School, 1916. pp. 45-6.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Annual Report of the Torpedo School, 1915. p. 38.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Annual Report of the Torpedo School, 1916. p. 47.

- ↑ Annual Report of the Torpedo School, 1916. p. 47.

- ↑ Annual Report of the Torpedo School, 1916. p. 48.

- ↑ Annual Report of the Torpedo School, 1916. p. 52.

- ↑ Annual Report of the Torpedo School, 1916. p. 54.

- ↑ Annual Report of the Torpedo School, 1916. p5. 55-6.

- ↑ Annual Report of the Torpedo School, 1916. p. 56.

- ↑ Annual Report of the Torpedo School, 1916. p. 47.

- ↑ Annual Report of the Torpedo School, 1916. p. 57.

- ↑ Annual Report of the Torpedo School, 1917. p. 33.

- ↑ Annual Report of the Torpedo School, 1916. p. 87.

- ↑ March. British Destroyers. p. 513.

- ↑ Grand Fleet Gunnery and Torpedo Orders. No. 305.

- ↑ Annual Report of the Torpedo School, 1917. p. 24.

- ↑ Annual Report of the Torpedo School, 1917. p. 26.

- ↑ Annual Report of the Torpedo School, 1918. p. 216.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 3.

- ↑ 168.00 168.01 168.02 168.03 168.04 168.05 168.06 168.07 168.08 168.09 168.10 168.11 168.12 168.13 168.14 168.15 Annual Report of the Torpedo School, 1918, p. 10. (G. 8472/18)

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Annual Report of the Torpedo School, 1916. p. 39.

- ↑ 171.0 171.1 Annual Report of the Torpedo School, 1917, p. 27.

- ↑ Annual Report of the Torpedo School, 1915, p. 37.

- ↑ Annual Report of the Torpedo School, 1916. p. 39.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

- ↑ Addenda (1911) to Torpedo Manual, Vol. III, 1909. p. 3.

- ↑ Annual Report of the Torpedo School, 1916. p. 39.

- ↑ Annual Report of the Torpedo School, 1916. p. 45.

- ↑ Annual Report of the Torpedo School, 1916. p. 45.

- ↑ 179.0 179.1 Annual Report of the Torpedo School, 1918, p. 8.

- ↑ Annual Report of the Torpedo School, 1916. p. 46.

Bibliography

- Annual Report of the Torpedo School

- March, Edgar J. (1966). British Destroyers: A History of Development, 1892-1953. London: Seeley Service & Co. Limited. (on Bookfinder.com).

- H.M.S.O., London Torpedo Drill Book, 1905 (Corrected to December, 1904). Copy in Tony Lovell's library.

- H.M.S.O., London Torpedo Drill Book, 1908 (Corrected to December, 1907). Copy in Tony Lovell's library.

- H.M.S.O., London Torpedo Drill Book, 1912 (Corrected to April, 1912). Copy in Tony Lovell's library.

- H.M.S.O., London (1914). Torpedo Drill Book, 1914 (Corrected to May 15) Copy in Tony Lovell's library.

Pages in category "Torpedo (UK)"

The following 27 pages are in this category, out of 27 total.

1

- 14-in Mark I Torpedo (UK)

- 14-in Mark II Torpedo (UK)

- 14-in Mark III Torpedo (UK)

- 14-in Mark IV Torpedo (UK)

- 14-in Mark IX Torpedo (UK)

- 14-in Mark V Torpedo (UK)

- 14-in Mark VI Torpedo (UK)

- 14-in Mark VII Torpedo (UK)

- 14-in Mark VIII Torpedo (UK)

- 14-in Mark X Torpedo (UK)

- 14-in Mark XI Torpedo (UK)

- 16-in Torpedo (UK)

- 18-in Mark I Torpedo (UK)

- 18-in Mark II Torpedo (UK)

- 18-in Mark III Torpedo (UK)

- 18-in Mark IV Torpedo (UK)

- 18-in Mark IX Torpedo (UK)

- 18-in Mark V Torpedo (UK)

- 18-in Mark VI Torpedo (UK)

- 18-in Mark VII Torpedo (UK)

- 18-in Mark VIII Torpedo (UK)